Surface treatments of metals

A well-proven and certified company.

Powder coating of up to 8,000 x 2,500 x 2,800 mm / 2,500 kg

Blasting - manual / robotic blasting of up to 7,000 x 5,000 x 5,000 mm / 2,500 kg

Phosphating - FE of up to 8,000 x 2,500 x 2,800 mm / 2,500 kg

Complete renovations of ALU discs

Transport from the customer’s site and back

Short delivery terms

Tradition and experience from 1999

Comprehensive cooperation

News

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

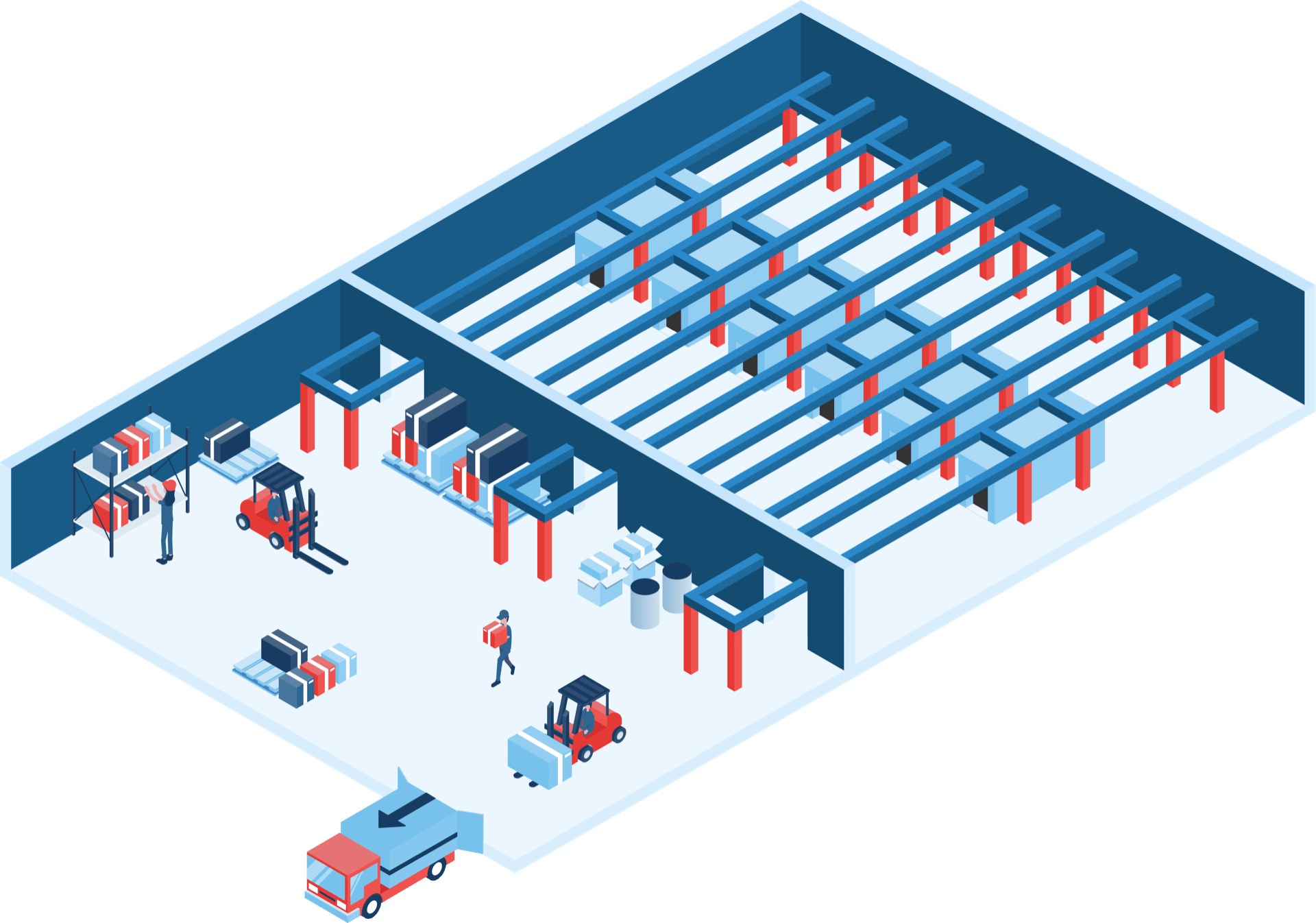

Procedure of surface treatments

1. Division of products for individual applications

- The division is followed by preparation of actual products

- Covering of threads and areas not to be coated

- Suspension of products on the overhead transport system

2. Manual blasting

- Intended for products with large dimensions 5 x 7 x 5 m / 2,500 kg

3. Robotic blasting

- Intended for products with small dimensions or products in series 3 x 1.6 m / 1,000 kg

4. Chemical pre-treatment by phosphating

- Possibility of phosphating of parts up to 8 x 2.5 x 2.8 m / 2,500 kg

5. Drying of parts

- After phosphating in the oven at 120 °C

- The product must be perfectly dry for the subsequent application of a coating material

6. Application of powder coating materials

- In spraying booths – the size of the largest part to be coated is max. 8 x 2.5 x 2.8 m / 2,500 kg

7. Curing of parts

- In the curing oven at a temperature of 180 – 200 °C

- Time of heating of the parts being 15 – 30 minutes

8. Packing of parts

- After the inspection and possible testing of adhesion of the coating material, including the layer thickness measurement, the part is ready for shipment

Our services

Powder coating

Blasting

Sweeping / zinc

Phosphating

Other services

OUR PARTNERS

Frequently asked questions

What is powder coating?

Modern surface treatment of metal products.

The principle is application of the powder coating material onto the part surface with subsequent curing in the oven. The powder coating material contains resins, pigment, or additives, and creates dry powder consistence. In order to ensure good adhesion of the powder coating material on the part, the application equipment supplies an electrostatic charge, and the part as such is grounded. The application of the powder coating material on the part uses compressed, dried and purified air which is produced in a compressor station, dried in an absorption dryer and purified by means of a special carbon filtration system.

Electrostatic energy uses the fact that particles with opposite charges attract each other. This fact causes attraction of powder coating particles to the sprayed part and adhesion on its surface. The powder coating material is cured at a temperature of 180 °C to 200 °C in the curing oven and adheres to the surface of the product. After 20 – 30 minutes of curing, the product is allowed to cool and is immediately prepared for shipment.

- The coated layer is resistant to impacts

- Good resistance to scratching

- Environmental friendliness

- Excellent external durability

What is blasting?

It is a well-known and rapidly expanding method of surface pre-treatment. The surface of the blasted object is cleaned, roughened or otherwise treated by blasting before its final treatment, such as coating or galvanisation. We use the compressed-air method, which is highly effective. This is a technological procedure of surface preparation used for various (usually hard) materials by using a stream of pressurised abrasive particles.

The surface is blasted at various levels:

- SA – blasting: It removes visible and non-adhesive scale, rust and other impurities. All residuals must fully adhere to the base.

- SA 2.5 – blasting on an almost clean metal: It removes visible scale, rust and other impurities. Any residual traces of impurities will appear only as light stains in the form of areas or belts.

- SA 3 – blasting on a fully clean metal: It removes all visible traces of scale, rust and other impurities. The surface has a uniform metallic appearance.

What is chemical pre-treatment by phosphating?

Phosphating is chemical treatment of surface of metal parts for the purpose of increasing the resistance to corrosion and improvement of adhesion for the next surface treatment. It is one of the most frequently used methods of chemical treatment of surfaces during which crystalline tertiary water-insoluble phosphates are created.

The crystalline layer arising during this process is insoluble in water and organic solvents. It has very good cohesion with base metal. Without any further treatments it is suitable as a conversion surface for coating. At present we offer suspension phosphating to our customers, when we remove gross impurities from metal parts at first, this is followed by phosphating at 60°C, rinsing with water and at the end rinsing with demineralised water.

Chemical pre-treatment is another important factor for the final quality of products.